Factories

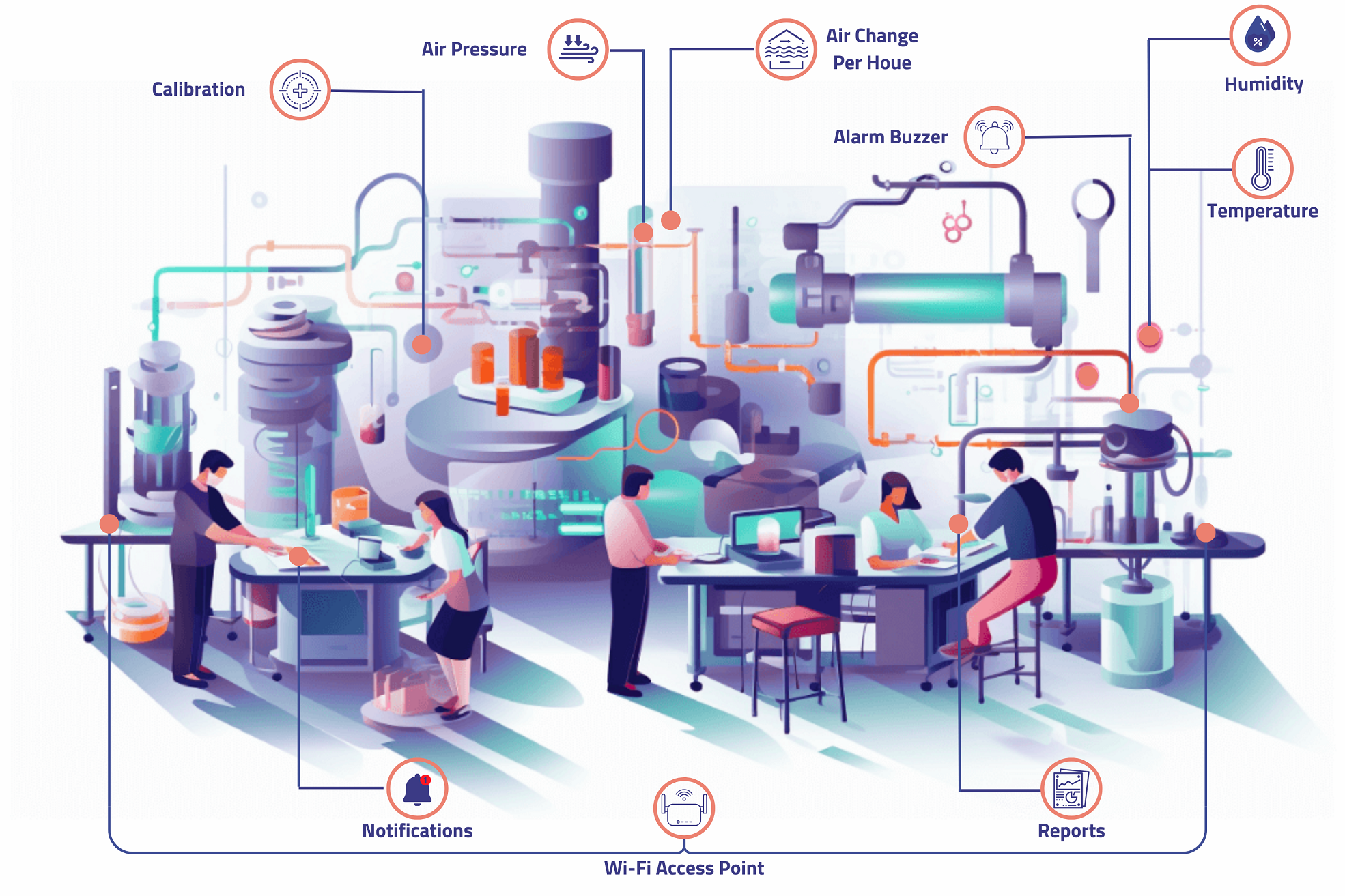

A temperature monitoring system is crucial for food and pharma factories to ensure product safety and regulatory compliance. It provides real-time data and alerts to prevent temperature deviations, reducing the risk of spoilage, contamination, and product loss. By maintaining consistent storage conditions, it enhances product quality, minimizes waste, and protects both consumer health and brand reputation.

Why does the Factories sector need temperature monitoring service?

- Regulatory Adherence: Ensures compliance with stringent global standards (e.g., FDA, EMA, WHO, HACCP, GMP) by maintaining precise temperature control throughout production and storage processes.

- Product Integrity Preservation: Safeguards the efficacy, stability, and shelf life of temperature-sensitive products, including biologics, vaccines, and perishable food items.

- Risk Mitigation: Reduces the likelihood of product spoilage, contamination, or degradation due to temperature excursions, minimizing financial and operational risks.

- Operational Efficiency: Automates temperature tracking, eliminating manual errors and streamlining workflows to enhance productivity and resource allocation.

- Real-Time Alerts and Intervention: Provides instant notifications for temperature deviations, enabling prompt corrective actions to prevent product loss or compromised quality.

- Audit and Compliance Readiness: Generates accurate, tamper-proof data logs for regulatory audits, inspections, and quality assurance documentation.

- Cost Optimization: Prevents costly recalls, waste, and rework by ensuring consistent environmental conditions, directly impacting the bottom line.

- Supply Chain Assurance: Maintains product quality during transit and storage, ensuring compliance with cold chain requirements and reducing liability risks.

- Enhanced Reputation: Demonstrates commitment to quality and safety, fostering trust among stakeholders, customers, and regulatory bodies.

- Sustainability and Waste Reduction: Minimizes environmental impact by reducing product waste and energy consumption through optimized temperature control systems.

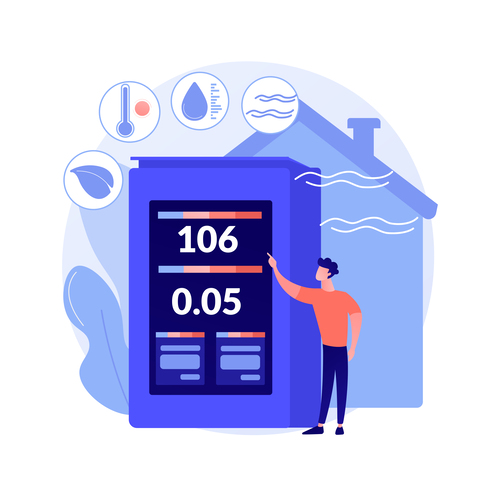

Temperature Live TRACKING

Temperature and Humidity Live Tracking is a real-time monitoring system that continuously measures and displays environmental conditions. It provides instant updates on temperature and humidity levels, ensuring optimal conditions for sensitive products, processes, or environments. With live data, users can quickly detect deviations, receive alerts, and take corrective actions to maintain quality, safety, and compliance. Ideal for industries like food, pharmaceuticals, and storage, it offers peace of mind and precision in environmental control.

Dashboard

A dashboard is a visual tool that consolidates and displays key information, metrics, and data in a single, easy-to-understand interface. It provides customers with a quick, real-time overview of critical insights, enabling them to make informed decisions without sifting through complex data. With charts, graphs, and summaries, dashboards simplify complex information, saving time and improving efficiency. Whether for tracking performance, monitoring systems, or analysing trends, dashboards empower users to access full information at a glance.

Alerts

Notifies you through system notification, email alert, beeping on the Hub when temperature & humidity exceeds the set value.Alert staffs in minutes when the temperature of any facility is abnormal. For example, the temperature of devices get too high quickly during the hot summer. To avoid facility, damage due to excessive temperature, administrator or staff would be notified to act in time. By doing so, it would avoid spending replacement costs and extending downtime.

Reports

Temperature and Humidity Reports provide detailed, historical data on environmental conditions over a specific period. These reports include trends, averages, and deviations, helping users analyze performance, ensure compliance, and identify potential issues. Essential for industries like food, pharmaceuticals, and storage, they offer actionable insights for maintaining optimal conditions, improving processes, and meeting regulatory requirements. Easy-to-read and comprehensive, these reports are a vital tool for quality control and decision-making.

Data analytics

Data analytics improves temperature and humidity monitoring by providing real-time insights, predicting issues, and optimizing conditions. It enhances efficiency, reduces costs, and prevents damage, ensuring ideal environments for industries like healthcare, and manufacturing. This leads to smarter decision-making and sustainable operations.

Integratable

Tems platform can seamlessly integrate with CRM, ERP, or other enterprise platforms, enhancing overall operational efficiency. By connecting monitoring data with CRM system.

Customizable:

The temperature and humidity monitoring system is fully customizable, designed to adapt to the unique needs of various industries and businesses. It allows users to set specific thresholds, configure alerts, and create tailored dashboards for real-time monitoring and reporting

Mobile App

The temperature and humidity monitoring system is supported by a user-friendly mobile app, providing real-time access to critical data anytime, anywhere. The app allows users to monitor environmental conditions, receive instant alerts, and view customizable dashboards directly on their smartphones or tablets. With features like remote control and historical data analysis, the mobile app ensures seamless management of temperature and humidity levels, even on the go.